UMP researcher produces milk coagulant using a mixture of extract of three local fruits

Kuantan, 8 September 2020 - Milk coagulation is the first process for the production of cheese or curd and is usually done using enzyme extracts from the stomach of unweaned young animals such as calves, kids and piglets.

Looking at this situation, the lecturer of the Faculty of Science and Industrial Technology (FSTI), Associate Professor Dr. Jaya Vejayan Palliah produced milk coagulant using a mixture of extracts of three local fruits, namely mango, pineapple and noni.

This research was also assisted by the Senior Dean, College of Management and Humanities, who is also a lecturer at the Centre for Human Sciences (PSK), Associate Professor Dr. Hasan Ahmad.

He shared his expertise in matters related to halal certification.

According to Associate Professor Dr. Jaya Vejayan, if we use fruits, we no longer need to use extracts from the stomach of young animals and at the same time do not raise halal issues for Muslims and also the ethics of sacrificing young animals.

“This idea started when researchers placed the venom of Malayan pit viper into a glass of milk. As a result, it could thicken milk.

“But I realise there is no commercialisation potential from something venomous from snake even though I can isolate and identify the coagulant components.

“Therefore, I shifted my focus to plants as a coagulant, and that is where the idea of this project began,” he said.

This research has started since 2016 and is expected to be commercialised as early as 2022 and no later than 2024.

“It all depends on the progress of the research and the commitment of researchers.

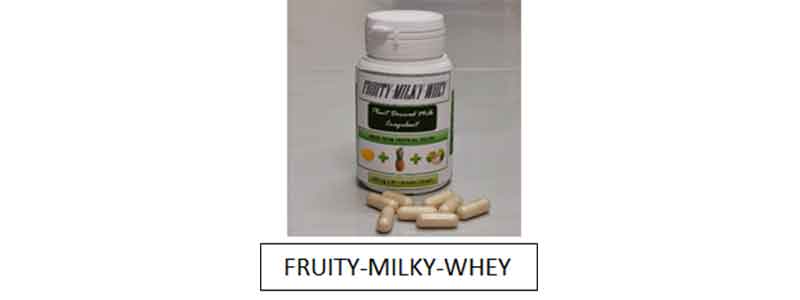

“This product is a capsule that contains three selected local fruits, namely mango, pineapple and noni.

“When a capsule is placed in a glass of hot milk, the capsule skin will melt within a short period.

“The mixture in the capsule will coagulate the milk into a semi-solid lump surrounded by the excess liquid (whey).

“When the excess liquid is filtered and discarded, the semi-solid lump can be converted into cheese,” he said.

So far, the study conducted has not yet involved external agencies, and this project was funded via UMP internal grant and several students’ PGRS grants.

Malaysia is currently heavily dependent on imports of fresh milk and dairy products from abroad, such as New Zealand and Australia.

“If this product is developed, it will be able to expand the country’s dairy industry and at the same time be able to promote local fruits.

“For Muslim consumers, they will be more confident to buy dairy products containing fruit extracts,” he added.

He will perform further research in the laboratory to have full confidence in fruit extracts before being successfully made into a product.

He also believes that the concept of milk coagulant from these fruits has great potential and needs to be developed until successful.

Previously, this product bagged a silver medal at the International Conference and Exposition on Inventions by Institutions of Higher Learning 2019 (PECIPTA’19).

He also produced two capsule products, namely Tongkat Ali Nina Square capsule (260 mg) and Tok Ali Bio-Root capsule.

Tongkat Ali Nina Square capsule (260 mg) is already in the market.

Tok Ali Bio-Root capsule, which is a mixture of three types of Tongkat Ali, will be in the market starting September 2020.

At the Creation, Innovation, Technology & Research Exposition (CITREX) 2020 organised by UMP on 12-13 February, this product won the gold medal and special award of the Biotechnology Excellence Award.

By: Nur Hartini Mohd Hatta, The Office of SUARA UMP

Translation by: Dr. Rozaimi Abu Samah, Engineering College/Faculty of Chemical and Process Engineering Technology